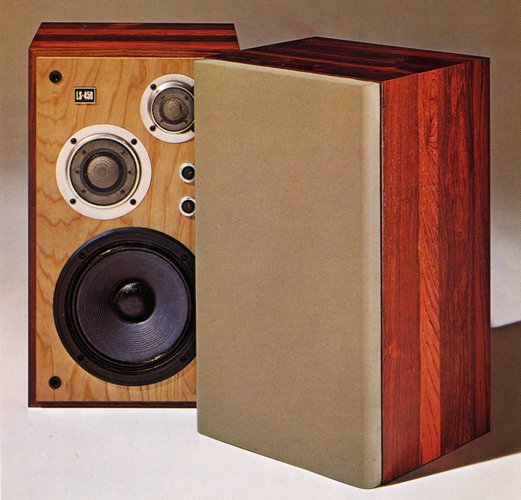

TRIO LS-450

¥ 43,000 (1 unit, around 1975)

Commentary

This speaker system is the second generation of the LS series equipped with a Japanese paper dome unit.

A 25 cm cone type woofer is installed in the low range.

A CF cone is used for the diaphragm of this unit. For the LS-450 and LS-350, in addition to the know-how accumulated from the development stage of the LS series, such as improvement of the beating method and degree of beating, press molding by increasing the water content, etc., we have developed and introduced new technology. By this, while taking advantage of the sound quality of the CF cone, which is simple and voluminous, with little peculiarity, we have improved the texture in the low sound range and sharpness.

The edge uses an asymmetric S-shaped edge that combines the advantages of a roll type and a reverse roll type. Since the same force is always applied to the support system, the edge does not deform at large amplitude.

A T-shaped pole piece is used in the magnetic circuit to achieve a uniform magnetic field. This reduces the amplitude distortion because the same force is applied to the amplitude of the voice coil. In addition, the surface where the voice coil contacts the pole piece is reduced, and the third harmonic distortion in the middle range can also be reduced. In addition, a hole is made in the center of the pole piece to release the air in the chamber, greatly improving the amplitude distortion.

For the core paper of voice coil, hard TLP with high Young's modulus and propagation speed is adopted.

A 5 cm dome type skoker is installed in the middle area.

The diaphragm is made of a mixture of CF pulp and Ganpishi to create a thin and strong diaphragm. The diaphragm made of CF pulp is lighter than soft domes and metallic domes, so it has high efficiency and provides a damping mid-range. In addition, an asymmetrical S-shaped edge is used for the edge section to provide a smooth amplitude and a low-frequency range with low distortion and good start-up.

A T-shaped pole piece is used in the magnetic circuit to obtain a uniform magnetic field, and in addition, a high magnetic flux density of 14,000 gauss is realized. In addition, the back pressure of the dome part is released by opening a large diameter hole of 20 φ in the pole piece. In addition, holes for air release are provided in the top plate and back plate to eliminate the resonance of the air chamber in the edge.

The Skoker unit has an iron molded 150 cc back cavity to achieve fo = 350 Hz, and resonance prevention rubber is attached to the cavity to reduce distortion.

A 2.5 cm dome type tweeter is installed in the high range.

The diaphragm of this unit is made of Japanese paper (Ganpishi), which has a higher Young's modulus and a higher propagation speed than Western paper. Since the fiber of this Ganpishi is thin and long, it can be processed thinly while maintaining its strength. It is also more advantageous than metals in terms of weight-to-strength ratio. In addition, it is superior in terms of high-frequency resonance because it has an appropriate internal loss. The diaphragm is made of stainless wool, which has a higher specific gravity than glass wool, so that the sound quality is rolled by t.

A T-shaped pole piece is used in the magnetic circuit to achieve uniform magnetic flux density. At the same time, sound absorbing material is put in the cavity between the magnet and pole piece to brake, and the Q of the fo resonance is lowered to improve sharpness.

For the frame part, we have adopted a projecting frame in which the dome part protrudes in front of the baffle. This improves the rise-up characteristics of the tweeter and realizes a tweeter with good damping. In addition, reflection in the high-frequency range is less likely to occur, and frequency characteristics are also improved. In addition, by inserting an diffuser using micron glass between the pretector and the diaphragm, the high-frequency range is moderately suppressed, and flat characteristics and directivity are improved.

The network section is designed for repeated trial listening with an emphasis on sound quality, and a film condenser is used for the condenser.

The attenuator is a continuously variable type with constant inductance so that it can be operated from the front.

The front and rear baffles are made of lumber core material, giving a clear and natural sound quality characteristic of muku material. The lumber core material is made of Chinese wood and is finished by sticking a single piece of cork tree on the surface.

A flexible board base stabilizer is attached to each side plate to suppress resonance of specific natural vibration to obtain high quality sound, and reinforcing bars are used to connect front and rear baffles to improve sound quality.

Glass wool with good air permeability and sound absorption is used for the sound absorbing material inside the enclosure, realizing excellent sound absorption effect and standing wave removal effect.

Model Rating

| Method | 3-Way, 3-Speaker, Airtight Type, Bookshelf Type |

| Unit | For low band : 25 cm cone type For Middle Area : 5 cm Dome Type For high-pass : 2.5 cm dome type |

| Playback frequency band | 35 Hz to 25 kHz |

| Max Input | 60W |

| Impedance | 8 Ω |

| Output sound pressure level | 90dB/W/m |

| Crossover frequency | 850 Hz, 6 kHz |

| Level control | Continuously variable type |

| External dimensions | Width 345x Height 590x Depth 324 mm |

| Weight | 14kg |

.jpg)