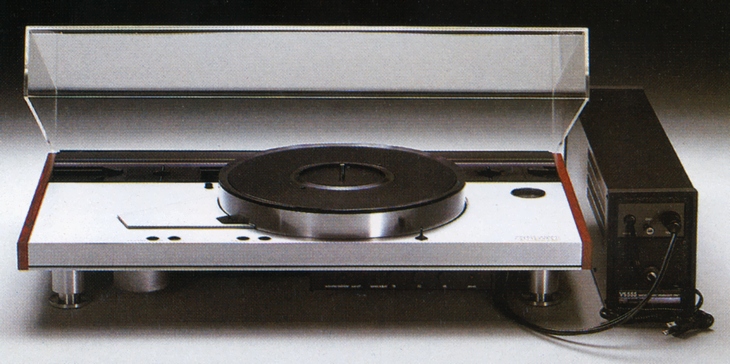

LUXMAN PD555

Set : ¥ 450,000 (released in April 1980)

Body PD555

: ¥ 330,000 (released in April 1980)

Unit VS555 : ¥ 120,000 (available April 1980)

Commentary

Turntable equipped with vacuum disk stabilizer.

Vacuum disk stabilizer

It employs a vacuum disk stabilizer that adsorbs and integrates the phonograph record onto the turntable, and completely eliminates the resonance of the phonograph record and the low-frequency resonance (5Hz-10Hz) of the arm and cartridge caused by warping.

The PD555 has a structure to connect an external stabilizer unit to a groove and an inlet on the turntable surface for air intake and an inlet passage inside the turntable. When the stabilizer is turned ON, the atmospheric pressure presses the record against the turntable. When the pressure is converted into weight, approximately 250 kg of stabilizer is applied to the adsorption part.

In order to realize an adsorption system, PD300 uses a vacuum pump. This vacuum pump is simple, applying the principle of bellows, and is the driving force for reliable adsorption operation. In addition, two grooves and an inlet are provided on the turntable surface as an air suction path, and an air passage is provided inside the turntable, which is connected to the pump by a tube.

Air-tightness is maintained for a long time after the stabilizer absorbs the phonograph. This is due to the sealing effect of the sealing pad installed on the turntable surface and the sealing ring and liquid packing (silicone) used to keep the air passage airtight.

Therefore, the stabilizer unit only needs to operate when air is sucked in and when air is released, so there is no effect of noise caused by the operation of the stabilizer unit.

The stabilizer can be turned on/off with the switch on the top of the player.

In addition, only one touch connection between the remote cable and the suction tube is required for the connection to the player body. Each of them is 2m long, so it can be installed freely according to the conditions of the installation place and room.

The degree of adsorption can be monitored by a vacuum meter on the top of the player.

When the stabilizer switch is turned on, the pump in the unit operates for one stroke. At the same time, the vacuum meter displays the degree of vacuum between the record board and turntable as the difference (unit : cmHg) from the outside air pressure.

High-precision meters for commercial use have been adopted to increase reliability as monitors.

Equipped with auto-stabilizer function.

With this function, the stabilizer can be linked to record rotation ON / OFF. If the auto-stabilizer selector switch located under the player board is set to ON, the auto-stabilizer is attracted at the start of record rotation and released at the stop.

Turntable part

The PD555 uses a turntable and sub-turntable structure.

The drive section uses a belt drive system, which is driven by a brush and slotless DC servo motor. Weight 8.5 kg, moment of inertia 1.2t ・ cm2By utilizing the powerful energy of the high inertia turntable, quiet record rotation is realized.

The turntable uses a cast system.

Instead of the die-casting method for mass production, we adopted a casting method that provides more precise accuracy. Using high-purity aluminum material, we created a new shape relatively slowly under pressure, and finished it with precision. This not only achieves high surface accuracy, but also thoroughly removes bubbles generated inside, making the density highly uniform. In addition, resonance is eliminated by making the shape close to a shape that can be called a mass with few inner dents.

The sub-turntable uses a surface receiving structure with a wide contact surface to completely eliminate the resonance of the turntable.

In addition, as with turntables, aluminum casts have been used to improve rotational accuracy. In particular, high accuracy has been given to the contact surface with the internal bearing part and the air intake passage part, and sufficient measures have been taken to maintain airtightness.

Cabinet part

The chassis structure consists of a 3-mm-thick steel plate and a 24-mm-thick laminated plywood sandwiched between extruded aluminum plates and aluminum plates. In addition, a damping adhesive tape with internal loss is used between the aluminum and plywood to ensure strength and eliminate resonance.

Uses LUX's original 2-stage braking type insulator for the leg part.

When an insulator is used to dump unwanted vibrations that are caused by external factors, the lower the fo (lowest resonance frequency) and the higher the Q (sharpness of resonance) at fo, the better the isolation characteristics against general vibrations. However, simply increasing the Q simply causes instability against large amplitude vibrations near fo.

In the PD555, the shaft is supported by neoprene rubber in a high-compliance state, and Q is raised to cut off small vibrations. For large amplitude vibrations, viscous braking of silicon grease is combined with a spring. This is a two stage braking system.

Arm base

In PD555, 2 arms including long arm can be mounted with one touch.

The arm is attached and detached using a sliding arm base. This method is inspired by the slide bed used in lathes. It can be attached securely with simple operation and can be positioned precisely. Slide the base along the arm rail and fix it at the optimum position by looking at the overhang gauge written on the panel surface.

The arm base is made of zinc die-cast considering the howling characteristics.

Other

Equipped with a rotating speed fine adjustment function, the rotating speed can be finely adjusted while watching the strobe installed beside the turntable.

The PD555 can be switched between 33 rpm, 45 rpm and 78 rpm. In addition, the strobe can be accurately adjusted by displaying a unique pattern on the back of the turntable with flashing light from a crystal oscillator.

Equipped with an overhang gauge.

Generally, it takes time to adjust the overhang by loosening the fixing screw of the cartridge. However, with the PD555, it can be done only by sliding the arm base. Moreover, the arm and cartridge can be easily replaced with a gauge provided on the panel surface.

It can also be used as a high inertia belt drive turntable without using the vacuum disk stabilizer.

For this purpose, it comes with a platter mat shaped to support only the sound groove part.

Model Rating

| Type | Record player | |||||||||||||||||||||||||||||

| Phono Motor Section | ||||||||||||||||||||||||||||||

| Drive system | Belt drive system | |||||||||||||||||||||||||||||

| Motor | Brush & slotless DC servo motor | |||||||||||||||||||||||||||||

| Turntable | 30 cm aluminum cast, 8.5 kg | |||||||||||||||||||||||||||||

| Moment of inertia | 1.2t / cm2 | |||||||||||||||||||||||||||||

| Number of revolutions | 33 rpm, 45 rpm, 78 rpm, 3-speed switching type | |||||||||||||||||||||||||||||

| Rotational speed adjustment range | ± 2.5%, each speed can be adjusted independently | |||||||||||||||||||||||||||||

| Signal-to-noise ratio | 60 dB or more | |||||||||||||||||||||||||||||

| Wow flutter | 0.03% or less (WRMS) | |||||||||||||||||||||||||||||

| Startup time | 4 seconds or less (1 revolution or less at 33 rpm) | |||||||||||||||||||||||||||||

| <General> | ||||||||||||||||||||||||||||||

| Pwer | 100 VAC, 50Hz/60Hz | |||||||||||||||||||||||||||||

| Power consumption | PD555:20W VS555:70W |

|||||||||||||||||||||||||||||

| External dimensions | PD555 : 664 mm wide x 175 mm high x 392 mm deep VS555 : 102 mm wide x 154 mm high x 512 mm deep |

|||||||||||||||||||||||||||||

| Weight | PD555:26.5kg VS555:7.0kg |

|||||||||||||||||||||||||||||

| Sold Separately | Arm Base Panel TP-SG (¥ 2,000) Arm Base Panel TP-MT (¥ 2,000) Arm Base Panel TP-LH (¥ 2,000) Arm Base Panel TP-LS (¥ 2,000) Arm Base Panel TD-X (¥ 2,000) |

|||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)