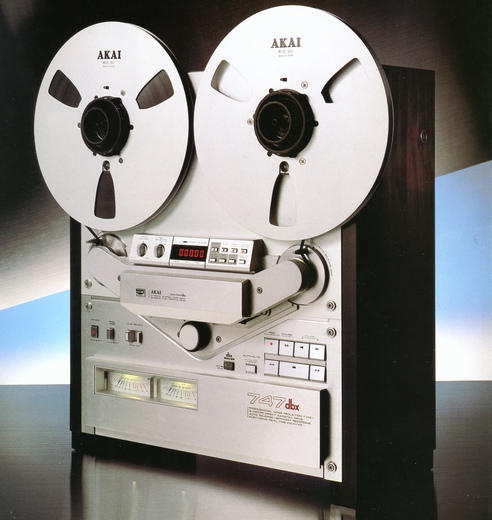

AKAI GX-747dbx

GX-747dbx : ¥ 230,000 (around 1982)

GX-747dbx BL : ¥ 234,000 (around 1982)

Commentary

A tape deck newly equipped with dbx Type1 based on GX 747.

Dbx Type1 is installed as a noise reduction system.

Dbx records music signals compressed to 1 / 2 of the decibel over the entire band and expands them to twice the level for playback. This expands the dynamic range of the tape to 128 dB and allows for more than 100 dB of dynamic range for live performance.

In addition, the noise level can be reduced by up to 30 to 40 dB in the entire audible frequency band, reducing tape hiss. Unlike the sliding band method, dbx performs linear logarithmic compression and expansion in the entire band, so there is no mistuning due to sensitivity differences between the tapes used, and there is no change in sound quality.

The GX 747 dbx is equipped with a professional version of dbx Type1. Since the operation control signal of dbx is detected in a wider band than that of the consumer version of Type2, high-frequency saturation characteristics are further improved.

The new GX head (Glass & X' tal Ferrite Head) developed by AKAI is used as the recording and reproducing head.

AKAI has selected ferrite, which has excellent dynamic characteristics, as a material, and succeeded in converting ferrite into low-noise crystal using its original material processing technology. The GX head uses this material for the head core and shield core, and the entire structure is hardened with high-hardness glass.

This solves the problems of conventional ferrite heads, such as noise and crystal grain falling, while minimizing eddy current loss and characteristic degradation in the manufacturing process. Moreover, it achieves higher permeability and saturation magnetic flux density than metal heads such as permalloy and Sendust. In addition, since high-hardness glass is used as a fusion material, the head cap has extremely high machining accuracy and excellent characteristics. In addition, it has excellent abrasion resistance and dust does not adhere to it easily.

The New GX Head also features a compound R-shape at the tip of the head to improve the contour effect and improve overall performance by strengthening the shield between tracks to reduce crosstalk.

The erase head uses a double-gap design with high erase efficiency.

Equipped with a tape selector, EE position can be selected.

The EE Position is a tape standard jointly developed by Akai, Maxell, TDK, and TEAC. Magnetic materials used in high-position cassette tapes and videotapes (Maxell : Epitaxial, TDK : Abilin) are newly used for open-reel. This makes it possible to significantly improve MOL characteristics and reduce noise levels in high-frequency ranges.

The recording / reproducing amplifier has also been improved to achieve higher sound quality. In particular, the recording amplifier has a wide dynamic range by introducing carefully selected high-quality elements, utilizing the latest electronic circuit technology, and strengthening the power supply.

An AC servo motor is used for the capstan drive motor in the mechanism.

An AC servo motor has advantages as an acoustic motor, such as less torque ripple that induces the generation of flutter components and less motor noise because it does not have a brush. In order to make this driving characteristic more perfect, the AC servo system with built-in CPG equipped with a sample-and-hold circuit with good servo characteristics is adopted. The output from the FG directly connected to the motor rotation shaft is converted into a pulse, and it is always compared with the reference pulse to realize high-precision rotation control.

In addition to thoroughly suppressing the vibration of the motor, AKAI's unique ultra-precision finish is applied to the capstan shaft to further improve the wear resistance of the capstan and the tape grip force, thereby reducing flutter components.

Dedicated AC motor is used for delivery and winding.

The drive mechanism uses a symmetrical tape drive mechanism, and the center capstan drive system, which is located at the center of six symmetrical heads, realizes extremely uniform driving characteristics in both directions.

In addition, the large guide rollers on the left and right sides of the head block bring the tape running close to the ideal horizontal running condition and provide optimum head touch in both directions. In addition, the distance between the guide rollers and the reel is extremely shortened, so disturbance vibration from the reel due to running is minimized. Moreover, the center capstan divides the tape path into two and provides appropriate tape tension, so that minute vibration of the tape near the head is also minimized.

In addition, in order to enhance the completion of the mechanism, an ultra-precision machining shaft is adopted for the guide roller, and in addition to transporting the tape without slip loss, it also works as a scrape filter and effectively absorbs tape vibration.

An oil damper system has been adopted for the tension arm to absorb sudden tape vibration at pre-start and to obtain excellent rise and characteristics.

Equipped with an auto-lock / release mechanism, the tension arm automatically locks when the tape is mounted, making it easy to pull the tape out to the head block, making it possible to mount the tape with one touch.

In addition, the tension arm is driven by a special motor, and when there is slack in the tape, the tension arm automatically applies tension to remove the slack and then enters the specified operation.

Direct function change method of feather touch operation is adopted for tape operation.

Equipped with a Oatley berth mechanism, it can last up to 6 hours (9.5cm/s, when using 150% tape).

Each of the system control and counter auto system is equipped with an independent dedicated microcomputer to improve operability.

The two microcomputers constantly exchange information with an LED electronic digital counter that displays hours, minutes, and seconds in real time up to 5 hours, 59 minutes, and 59 seconds. Five auto systems are available. They are equipped with preset memory auto-reverse function, immediate memory auto-reverse function, lap counter function, count-up function, and auto 0 stop function.

The preset memory auto-reverse function allows Oatley berth from any position by presetting the reverse point.

When recording, you can record back and forth continuously by setting the reverse point. When playing back, if you set the reverse selector continuously, Oatley verse is repeated between 0 : 00 : 00.

The quick-acting memory auto-reverse function enables Oatley birth at any position with one touch operation while the tape is running.

If the reverse selector is set continuously, memory auto-reverse playback between 0 : 00 : 00 and is possible.

The lap counter function can measure a specific program time during recording and playback separately from the tape counter set at the beginning. At this time, the counter set at the beginning also continues to operate. If the lap counter function is disabled, the normal tape counter will be displayed.

With the count-up function, both forward and reverse counts can be added and displayed during recording and playback.

Since the count can be added and displayed even if the tape direction is reversed during reciprocal recording and playback, calculation of program time, etc. can be performed easily.

The Auto 0 Stop function automatically stops the tape at 0 : 00 : 00 when the tape is being rewound or fast-forwarded in the count decrement direction. At this time, the tape stops while decelerating, so that there is no need to worry about damaging the tape.

It is equipped with a cue / review mechanism that can fast-forward and rewind while playing.

Equipped with an auto mute mechanism that can automatically create a 4 second silent recording portion.

Equipped with a memory marker with friction stop convenient for fade-in / fade-out.

Equipped with VU meter conforming to BTS standard.

Equipped with a bias adjuster that can be varied by ± 30%.

It is equipped with a pitch control that can change the tape speed during playback within ± 6% range.

Microphone and line mixing is possible.

Equipped with a recording mode selector to prevent accidental erasure.

Equipped with a reel size selector that can obtain an appropriate tape tension according to the reel size.

Equipped with a 3-stage switching reverse selector that can switch between one way re-recording, reciprocating re-recording and endless playback.

It has an output volume.

Equipped with a timer start mechanism.

There are 2 color variations of black and silver.

A separately sold remote control unit can be used.

Model Rating

| Type | Tape deck |

| Track system | 4-track 2-channel stereo system |

| Reel | Model 26 (No. 10) |

| Tape speed | 19cm/s (± 0.8%), 9.5cm/s (± 1.0%) |

| Wow and flutter | 19cm/s : 0.03% Wrms (JIS), ± 0.045% Wpeak (EIAJ) 9.5cm/s : 0.04% Wrms (JIS), ± 0.065% Wpeak (EIAJ) |

| Frequency characteristic (When using tape for EE position) |

25 Hz ~ 33 kHz ± 3 dB (19cm/s) 25 Hz ~ 25 kHz ± 3 dB (9.5cm/s) |

| Distortion factor | 0.4% or less (1 kHz, 0 VU, 19cm/s, 3rd harmonic distortion factor) |

| S / N ratio (19cm/s) | 65dB(JIS) 63dB(EIAJ) 100dB(dbx on) |

| Dynamic range | 128 dB (dbx on, 1 kHz peak level) |

| Heads | 2 x GX Recording Heads 2 GX Playheads 2 Erase Heads |

| Motor | One AC servo direct capstan motor 2 AC Eddy Current Reel Motors |

| Fast-forward rewind time | Approximately 75 seconds (when using 360m tape on No. 10 reel) |

| Input level | Microphone : 0.25 mv Line : 70 mV |

| Output level | Line : 410 mv Headphones : 1.3 mW |

| Power supply voltage | 100 VAC, 50Hz/60Hz |

| Power consumption | 80W |

| External dimensions | Width 440x Height 493x Depth 256 mm |

| Weight | Approx. 23.2 kg |

| Attachment | Connection code x2 Set Empty Reel x1 One sensing tab Reel Hub Adapter x1 Set One AC adapter |

| Sold Separately | Wired Remote Controller RC-21 (¥ 6,000) Wireless Remote Control RC-90 (¥ 18,000) |

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)